Standard Cost Definition, Examples What is Included?

- 2024-01

- by Cn Vn

But many taxpayers miss out on this valuable tax break because they don’t know which expenses are eligible or how to claim them. Standard hour means a hypothetical hour, which represents the amount of work that should be performed in one hour under standard conditions. Each article on AccountingProfessor.org is hand-edited for several standard costing dimensions by Benjamin Wann. My site utilizes a unique process that leverages AI and human subject matter expertise to create the best content possible.

Benefits of Standard Costing

Similarly, when establishing a standard costing system, the management of the business should establish different cost centers within the business. Cost centers are departments or areas of the business where costs are incurred. This allows standards to be set for specific cost centers that are relevant to those centers. Moreover, this allows costs to be easily traceable and comparable for that cost center with the standards set.

Business

- Additionally, standard costing is useful for performance evaluation, as it allows managers to measure efficiency and cost-effectiveness by comparing actual results against predefined standards.

- These standards are determined in the form of either quantity or monetary value.

- This includes the definition, objectives, types of performance standard as well as the advantages and disadvantages of it.

- Basic standards are, however, well suited to businesses having a small range of products and long production runs.

- Basic standards are set, on a long-term basis and are seldom revised.

- You must itemize your deductions on Schedule A, however, so the total of your deductions needs to exceed that 7.5% threshold for it to be worthwhile.

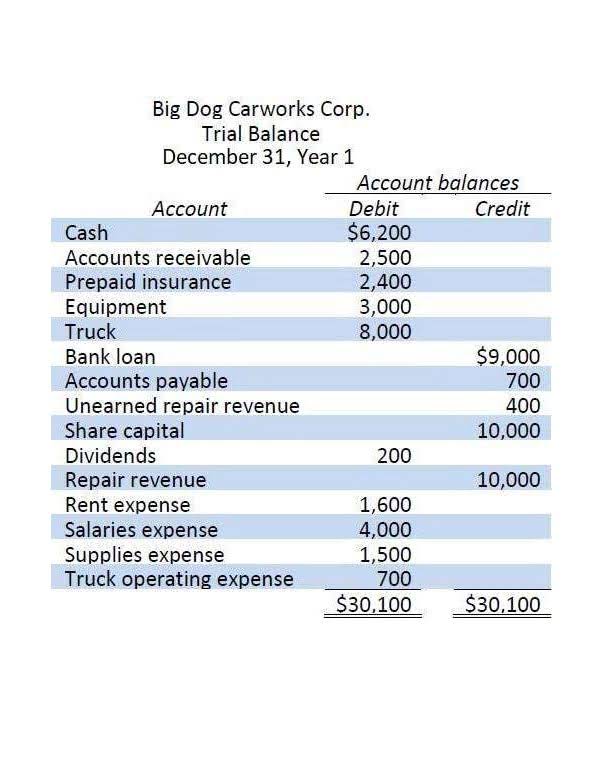

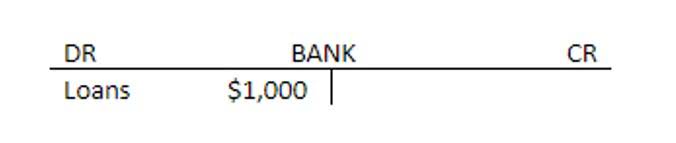

A manufacturer must disclose in its financial statements the actual cost of materials on hand as well as its actual cost of work-in-process and finished goods. Assume your company’s standard cost for denim is $3 per yard, but you buy some denim at a bargain price of $2.50 per yard. For each yard of denim purchased, fixed assets DenimWorks reports a favorable direct materials price variance of $0.50. Therefore, the total hours required for producing one unit is 10 hours. With standard costing, the general ledger accounts for inventories and the cost of goods sold contain the standard costs of the inputs that should have been used to make the actual good output. Differences between the actual costs and the standard costs will appear as variances, which can be investigated.

How to Calculate Standard & Actual Costs

When managers compare standard costs to actual costs, they can determine where or if new, more efficient business practices are required. Therefore, deviations are based on either change in quantity or changes in cost from the expected amount. The rate and volume variance categories for direct materials, direct labor, and overhead are where the most frequent variances that a cost accountant chooses to report are divided.

- A high level of technical skill is needed from the person setting the production cost, making it challenging to do so.

- For instance, you could divide the hourly price of electricity by four to calculate the cost of electricity per unit if an electric machine can produce a good in 15 minutes.

- You run your machines longer when you’re producing more, which raises your electricity costs.

- Analysis of variances between standard costs and actual costs provide vital information useful in improving and maintaining efficiency of operations.

- Because the variance occurred several weeks ago, some of the data may no longer be relevant, even though it could still be helpful.

- Accounts should be organized to reflect each cost center’s components accurately.

The standard cost of direct labor is the total cost of labor required to produce a unit of a product or provide a service. It is computed by multiplying the standard rate of an hour of direct labor by the standard hours required to produce one product. Standard cost accounting can hurt managers, workers, and firms in several ways. For example, a policy decision to increase inventory can harm a manufacturing Retail Accounting manager’s performance evaluation. Increasing inventory requires increased production, which means that processes must operate at higher rates.